What is Inventory Management?

It feels like you're drowning in products, doesn't it? Boxes are everywhere, you're not sure what you have, and you're terrified you sold something you don't actually own. This chaotic feeling is a clear sign you need to get a handle on your inventory management.

Getting a good system to manage inventory isn't just for huge corporations; it's a lifeline for businesses of any size. Having too much stuff on hand ties up your cash. You can't use that money to grow your business, pay your staff, or even pay yourself.

But having too little stock means you miss out on sales and frustrate your customers, who will happily go to your competitor. This balancing act is where a smart strategy comes into play, turning chaos into predictable profit. Good inventory management is fundamental to your success.

What Exactly Is Inventory Management?

At its heart, inventory management is the process of ordering, storing, using, and selling a company's inventory. This includes the management of raw materials, components, and finished products. The complete inventory management process covers the entire flow of goods from purchasing all the way to order fulfillment.

But it's so much more than just counting what's on your shelves. It's about knowing what you have, where it is, and how much you'll need in the future to meet demand. Proper management means your business and its supply chain can operate smoothly without costly interruptions, helping you fulfill orders efficiently.

Why You Can't Afford to Ignore It

Poor inventory control directly hits your bottom line. It's not a small leak; it can be a massive hole in your company's finances. The costs of mismanaging your goods can add up quickly and quietly, impacting your total costs of operation.

One of the biggest hidden costs is holding costs, also known as carrying costs. This is the money you spend just to store unsold inventory. Experts suggest these holding costs can be 20% to 30% of your inventory's total value, which includes storage space, insurance costs, labor, and potential spoilage of inventory sitting on shelves.

But the problems don't stop there. Here are a few other ways poor chain management hurts you:

- Stockouts: This happens when you run out of an item. You lose the immediate sale, and you might lose a customer for good, damaging customer satisfaction.

- Overstocking: This is having excess inventory, which ties up your cash in products that aren't selling. It leads to bigger holding costs and forces you to sell products at a deep discount, hurting your margins.

- Spoilage and Obsolescence: If you sell perishable goods, they can expire. For other products, they can become outdated or irrelevant, making them worthless and impossible to sell.

- Wasted Time: How much time do your employees spend searching for items? Disorganized stock kills productivity, increases labor costs, and slows down your ability to fulfill orders.

Key Inventory Management Techniques

You don't need a fancy degree to understand some powerful inventory management techniques. Many successful businesses use simple, proven methods to keep their stock levels under control. Getting familiar with these common methods can completely change how your business operates.

These management techniques help you make smarter decisions. You'll know what to order, when to order it, and how much you really need. This helps you keep cash flowing, improve inventory turnover, and maintain high customer satisfaction.

Economic Order Quantity (EOQ)

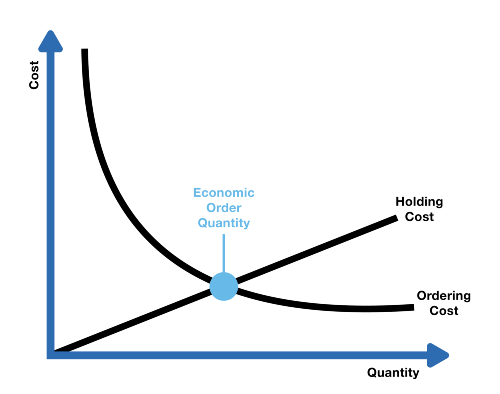

A classic management technique is the Economic Order Quantity (EOQ). The EOQ model is a formula used to determine the ideal order quantity a company should purchase for its inventory. The goal is to minimize the total costs associated with ordering and holding stock.

The calculation balances two competing costs: the cost of placing an order and the cost of holding inventory. Ordering in bulk might reduce your per-unit cost and ordering frequency, but it increases your holding costs. The EOQ model finds the sweet spot, the economic order point that keeps both costs low.

Using the EOQ helps you standardize your purchasing process. It removes guesswork and bases your purchase order decisions on hard data. This is a foundational step in building an effective inventory strategy.

ABC Analysis

The ABC method is a way to prioritize your inventory. It's based on the Pareto Principle, which suggests that about 80% of the effects come from 20% of the causes. In inventory terms, a small number of your items likely account for most of your revenue.

You categorize your products like this:

- A-Items: High-value products that make up a small portion of your stock but a large portion of your revenue. These need close attention and tight inventory control.

- B-Items: Mid-range products with moderate value and sales volume. They require less monitoring than A-items but more than C-items.

- C-Items: Low-value products that make up the bulk of your stock but a small part of your revenue. You can manage these with more relaxed rules and less frequent counting.

This inventory management technique helps you focus your time and money where it matters most. You won't waste effort constantly counting low-value items. Instead, you'll focus on protecting your most profitable products, a cornerstone of good inventory management.

Just-in-Time (JIT)

Just-in-Time, or JIT, is a strategy to reduce waste and carrying costs. With JIT inventory management, you receive goods from suppliers only as they are needed for production or for sale. The goal is to minimize the amount of inventory on hand at any given time, sometimes reducing stock based targets to near zero.

This approach was famously pioneered by Toyota to improve efficiency and is a core part of lean manufacturing inventory practices. It requires a lot of coordination and a reliable supply chain. Because if a delivery is late, your entire production line can shut down, so strong supply chain management is essential.

But when JIT inventory works, it frees up a huge amount of capital. It also helps to reduce waste from spoilage or obsolescence. It forces a more streamlined and efficient operation because there's no room for error or excess.

FIFO and LIFO

FIFO and LIFO are methods for valuing your inventory, which affects both your financial statements and warehouse management. They determine which costs are assigned to the cost of goods sold. Your choice impacts both your taxes and your reported profit.

FIFO stands for First-In, First-Out. It assumes the first items you purchased are the first ones you sell. This method is perfect for businesses selling perishable products, like food or makeup, as you want to move the oldest hand inventory first to avoid spoilage.

LIFO means Last-In, First-Out. It assumes the most recently purchased items are sold first. During times of rising prices, using LIFO can result in a lower taxable income because your cost of goods sold is higher.

No matter how well you plan inventory, demand can be unpredictable. That's where safety stock comes in. It's a small, extra amount of inventory you keep on hand to prevent stockouts from unexpected demand spikes or supplier delays.

A reorder point tells you when it's time to order more stock. It's the inventory level that triggers a new purchase order. To figure out your reorder point, you need a simple calculation that relies on accurate demand forecasting.

Here's how to calculate it:

- Determine your average daily sales for a product from your inventory data.

- Find the lead time from your supplier in days. This is how long it takes for your order to arrive after you place it.

- Multiply your average daily sales by the lead time to get your demand during lead time.

- Add your safety stock amount to that number.

The final number is your reorder point. When your stock level for that item hits that number, you know it's time to place another order. This takes the guesswork out of purchasing and helps you effectively meet demand.

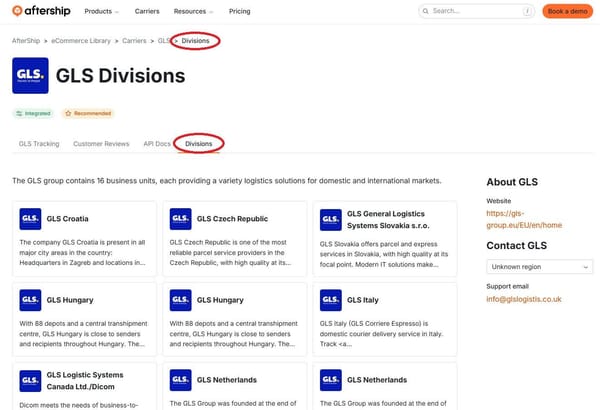

Tools for Better Inventory Management

Relying on pen and paper or your memory just won't work as your business grows. You need tools that can keep up with the demands of your operation. Thankfully, there are options for every stage of business growth, from simple spreadsheets to sophisticated inventory management systems.

Spreadsheets: The Starting Point

Many small businesses start with spreadsheets. They are accessible, and most people already know how to use them. For a very small operation with just a handful of products, this can be enough to start managing inventory.

But spreadsheets have serious limits. They are prone to human error, which a famous JPMorgan case showed can be incredibly costly. They also don't offer real-time updates, which means multiple people can't work in them at once without causing version control problems and data conflicts.

You'll probably outgrow your spreadsheets sooner than you think. As your business gets more complex and your need for accurate inventory data increases, you will need a more powerful solution. Manual tracking is simply not scalable for a growing business.

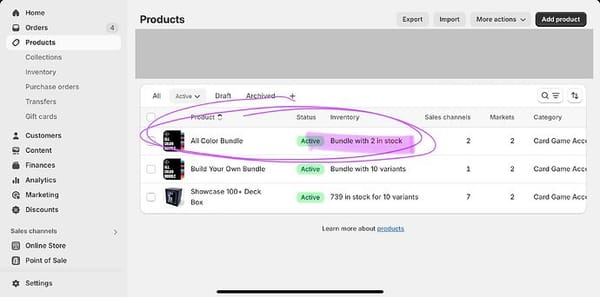

Inventory Management Systems

This is where dedicated inventory management systems come in. These software systems are built to automate and streamline the entire inventory management process. They offer features that spreadsheets simply can't match, providing a central hub for all your inventory works.

Modern software can track your stock across multiple locations in real time, supporting perpetual inventory management. It can automate your reorder points based on preset rules, so you never have to think about them. Many inventory systems can also generate forecasts based on your sales history through advanced demand planning tools.

Choosing the right software can feel like a big step, but effective inventory systems offer huge benefits.

Learn more about which inventory management software is best for you!